UT400

Complete turn-key CNC Seal Manufacturing Systems

UTEC Sealing Solutions offers you the latest technology in CNC machining systems, state-of-the-art computer technology and seal production software as well as high-performance sealing materials – the complete solution for modern seal production up to 400mm OD.

UTEC CNC lathes are custom-made, fully integrated systems, for the instant production of various seals used in hydraulic and pneumatic applications, as well as engineered plastic parts.

Machine, software, semi-finished materials and tools are precisely tuned to guarantee efficient machining and top-quality products.

Lathe-cut seals gain an ever-increasing market share in today´s sealing industry and are widely accepted in OEM and MRO applications — UTEC Sealing Solutions contributes its part to the success of this manufacturing technology.

High-end Technology

The machines are based on custom-designed lathes for metal machining and are modified and upgraded in our factory with all the features necessary for the machining of seals and plastic parts.

All machines are equipped with high-end mechanical and electrical/electronic components. The high precision guides, disc turret, bearing, drive systems and control unit are without exception produced by world-wide, well-known brands who define the standards of modern CNC machining technology.

These top-quality components in combination with a sturdy machine design guarantee a long service life of UTEC Seal Manufacturing Systems.

In order to guarantee the smooth operation of your UTEC CNC lathe, our customers will receive training on their machine, in our factory. After technical acceptance of the machine, it will be commissioned and installed on site by one of our engineers.

Technical Features

UT400

- Complete machine system for the production of seals up to 400mm OD

- Duplomatic 12-station tool turret with VDI-20 tool clamping system

- Latest FANUC Oi-T* drive and control system

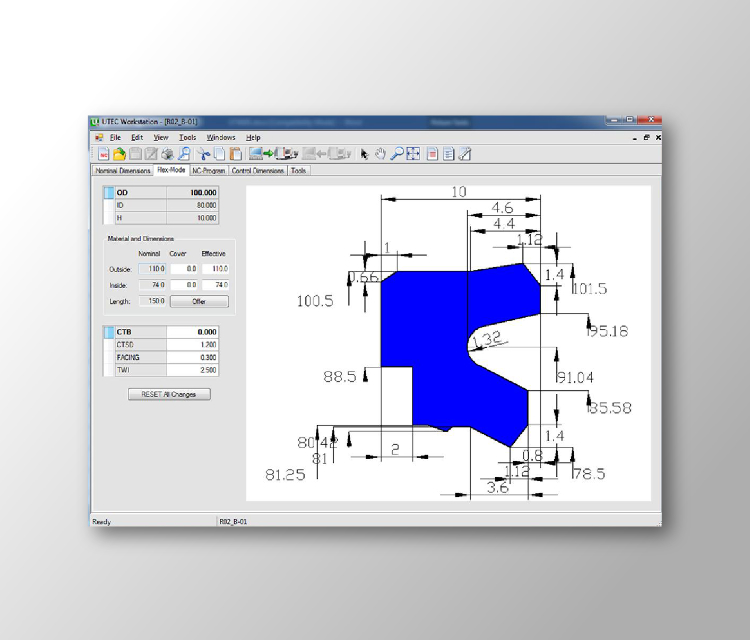

- PC with UTECFLEX software

- Chip cutter & suction unit

- Material clamping system

- Cutting tools & holders

- Automatic lubrication system

- Coolant (cutting fluid) system

- Accu-Finish tool lapping machine (optional)

Machine Components

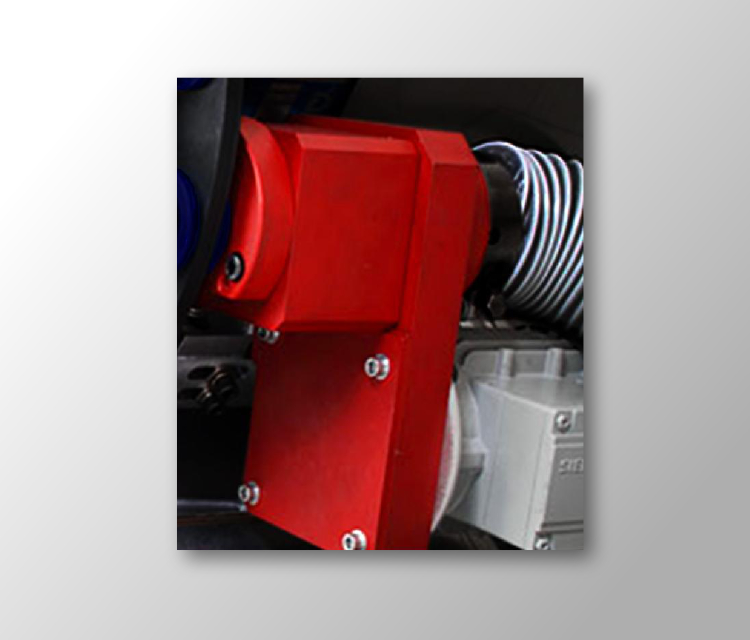

Control & Drive System

UTEC machines are equipped with the latest technology of FANUC, the world-wide leader of control systems for machine tools. The FANUC 0i-T* 2-axis control and the iServo-Drive System offer a state-of-the-art, high precision machine control system with high efficiency and reliability.

Tool System UT400

The turret disc on the UT400 model comes with a fast insert clamping system for up to 12 tools and guarantees a fast tool change.

Tools & Holders

The quality of cutting tools is of highest importance in the production of lathe-cut seals. A complete set of high-precision cutting tools made of fine-grain carbide is supplied with every UTEC machine. In order to cover the complex, complete range of existing seal profiles, most tools have a special geometrical shape and are custom made for seal production.

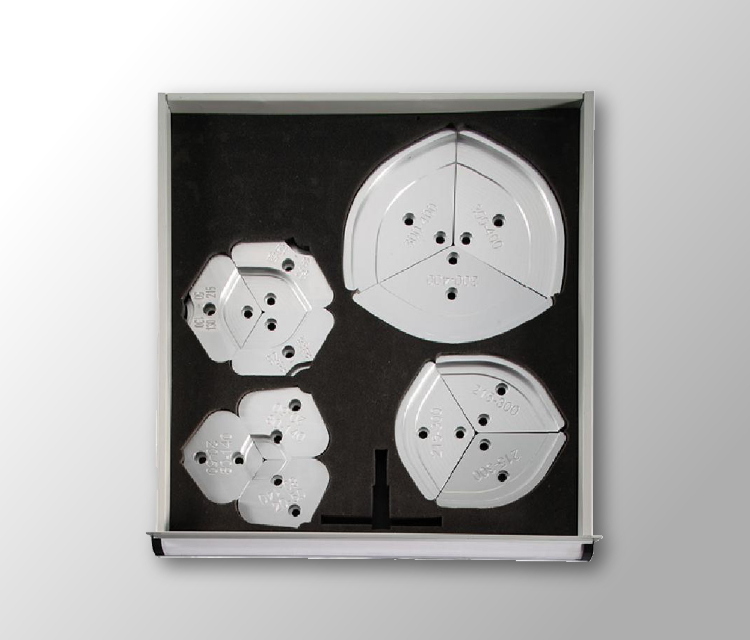

Material Clamping System

In order to efficiently clamp the raw material billets, special clamping jaws are mounted on to the steel body of the high-precision 3-jaw machine chuck. These sets of multi-range clamping jaws are made of high-grade aluminum and are designed to clamp certain diameter ranges of semi-finished billets.

Chip Cutter & Suction Unit

A well working chip cutter and suction unit play an important role in the manufacturing process of seals and engineered plastic parts, as they contribute to preventing swarf buildup around the tool and thus to a better surface finish of the end product.

The chip cutter is made of high-grade aluminum, using HSS tools to hack up the chips and keep the tools clean for optimal machining performance.

Optional Accessories

UTEC recommends the Accu-Finish tool lapping machine in combination with a microscope to sharpen, and verify the state of, tool tips. This tool lapping technology is highly efficient, as it substantially increases the service life of a cutting tool, and guarantees optimal tool sharpness, which in turn assures excellent surface quality of your end product.

Other accessories, such as measuring devices, bevelling shears, band saws for cutting guide rings etc can be supplied on request.